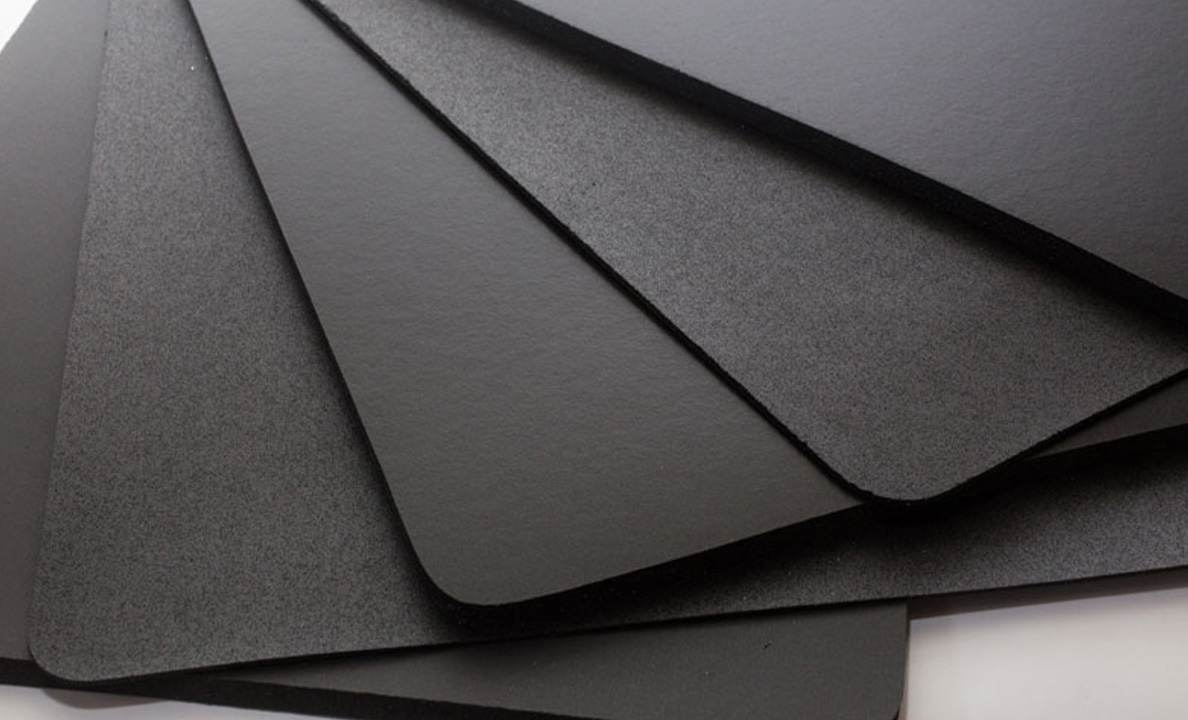

Lamination is a critical manufacturing process used to create composite materials by bonding multiple layers of various materials. At Foamtec, we utilize heat, pressure, and adhesives to laminate not only polyurethane (PU) foam but also a range of materials including polyethylene (PE), polypropylene (PP), rubber, felt, and other specialized substrates. This process enhances the physical properties of the final product, improving strength, durability, and resistance to environmental factors—serving industries such as packaging, construction, automotive, electronics, and medical.

Lamination

Experience The Foamtec Way

Lamination at Foamtec Specialty Converting

Heat Lamination

Heat lamination is a key process where materials are bonded together using controlled heat and pressure. Whether laminating PE foam for protective packaging, PP foam for automotive seating, or rubber for gaskets and seals, this method strengthens material properties such as durability, insulation, and flexibility. The precise control over temperature and pressure ensures optimal bonding for high-performance applications, including automotive interiors, insulation products, and custom protective solutions.

By automating the heat lamination process, we achieve consistency, precision, and efficiency, producing high-quality products suitable for demanding applications. Manual heat lamination remains available for smaller-scale or highly customized projects that require meticulous attention.

Automatic vs. Manual Lamination

At Foamtec, we offer both automatic and manual lamination processes, depending on the specific project requirements:

Automatic

Automated systems efficiently apply heat, pressure, or adhesives to bond layers of foam, rubber, felt, or other materials. This process ensures consistent quality, making it ideal for high-volume manufacturing. Foamtec’s custom-designed equipment guarantees precision and cost-efficiency, producing durable laminated products across a range of industries.

Manual

For specialized applications or smaller production runs, manual lamination allows skilled operators to handle complex materials and ensure high-quality results. This process is ideal for custom applications requiring more flexibility or control over the lamination.

Automatic

Automated systems efficiently apply heat, pressure, or adhesives to bond layers of foam, rubber, felt, or other materials. This process ensures consistent quality, making it ideal for high-volume manufacturing. Foamtec’s custom-designed equipment guarantees precision and cost-efficiency, producing durable laminated products across a range of industries.

Manual

For specialized applications or smaller production runs, manual lamination allows skilled operators to handle complex materials and ensure high-quality results. This process is ideal for custom applications requiring more flexibility or control over the lamination.

High-Performance Solutions

At Foamtec Specialty Converting, our lamination process brings together a variety of materials to create high-performance, durable solutions tailored to meet the demands of multiple industries.