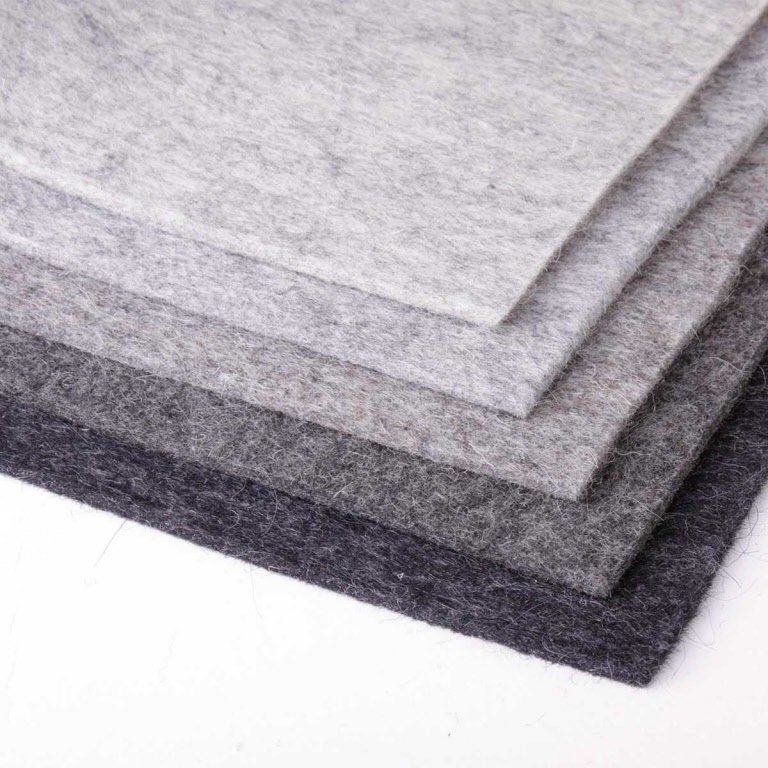

Resin Felt Material

The automotive industry is witnessing a pivotal transformation from Internal Combustion Engine (ICE) vehicles to Electric Vehicles (EVs). Central to this transition is the role of resin felt, a material known for its mechanical strength, adhesion to metals, and resistance to heat and moisture. This transition signifies a technological shift and highlights the evolving material requirements in vehicle manufacturing.

Resin felt, traditionally used in automotive coatings for ICE vehicles, offers protection against corrosion and enhances durability. Resin felt combines a viscous substance derived from plants or synthetically produced laminated to matted felt for increased durability, water resistance, and stiffness. It can be made in application-specific colors. Its application extends to battery packs in EVs, providing vital resistance to chemicals, moisture, and thermal shocks, thereby ensuring safety and longevity. The material’s significance is amplified in the context of EVs, contributing to the vehicles’ structural integrity and aesthetic appeal.

The transition to EV manufacturing involves a paradigm shift in production processes. EVs, characterized by fewer moving parts, eliminate the need for traditional ICE vehicle components like exhaust systems and fuel injectors. This simplification leads to more streamlined assembly lines and lower labor costs. Foamtec’s expertise in foam technologies positions them to adeptly navigate these changes, catering to the unique requirements of EVs with custom resin felt foams.

Foamtec International, a key player in the automotive sector, leverages its extensive experience in working with resin felt and other foam components to meet the demands of both ICE and EV manufacturing. Their product range includes specialized components for engine parts, windshield and door seals, and tires and roofs. Foamtec’s commitment to innovation and quality, backed by cutting-edge technology and a team of seasoned engineers, enables it to serve leading automotive manufacturers globally.

The global supply chain is critical in the EV market. With rising demand and part shortages, having a vertically integrated global company like Foamtec International is vital. We are the only company that manufactures our foam and then fabricates it into your end component, reducing the reliance on outside sources for materials.

As the automotive industry continues its march towards an electric future, the importance of materials like resin felt becomes increasingly pronounced. With companies like Foamtec International at the forefront, the industry is well-equipped to embrace the challenges and opportunities of this transition, ensuring that the vehicles of tomorrow are more efficient and environmentally friendly and maintain the highest standards of quality and performance.

Please get in touch with us today to learn more about differentiating your product line with unique resin felt.