The manufacturing sector stands at a crossroads where sustainability and efficiency are imperative for success and environmental stewardship. Foamtec International, with extensive die-cutting experience, exemplifies how innovative tooling design can prevent scraps from ending up in landfills. This article explores Foamtec International’s focus on material conservation, cost savings, waste reduction, and the reduction of carbon emissions through optimized die-cut tooling design.

The Significance of Die Cut Tooling Design in Waste Management

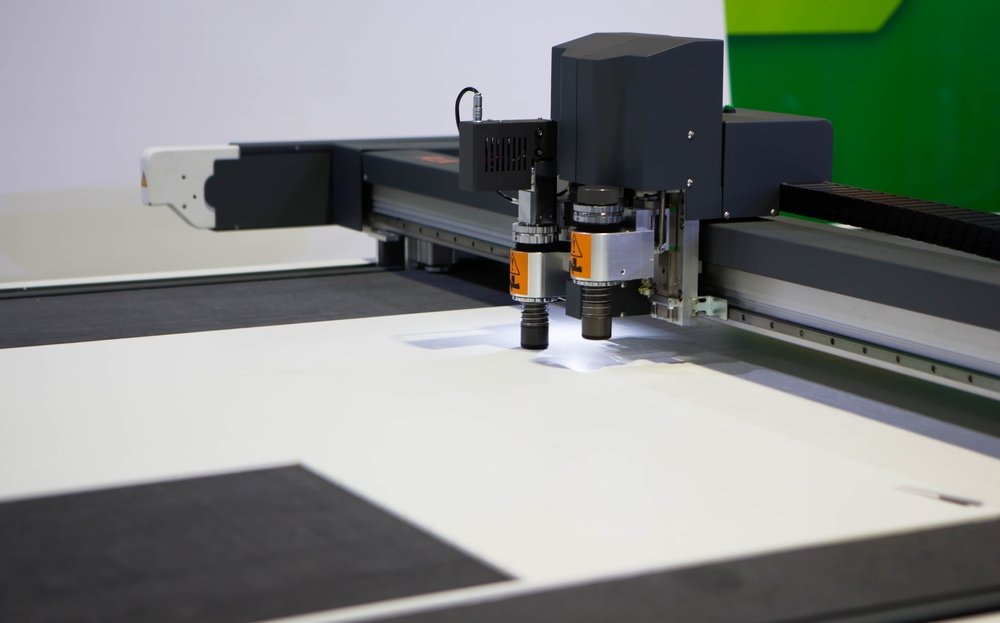

Die cutting is a precision process that shapes materials into specific forms. The design of these tools directly affects material usage, process efficiency, and the quality of the final product. Foamtec International leverages technology to prove that efficient die-cut tooling design can ensure high-quality production. Benefits include enhanced material usage and streamlined operations.

Material Conservation and Cost Savings

At the heart of Foamtec International’s approach is a commitment to material conservation. The company significantly reduces material waste by optimizing the layout for die-cutting. This leads to substantial material and cost savings, conserves resources, and exemplifies Foamtec’s role in driving sustainable manufacturing practices.

Reducing Industrial Waste

Foamtec International’s innovative tooling designs substantially decrease the volume of scrap material and contribute to waste reduction efforts. This innovation aligns with global sustainability goals and the company’s commitment to reducing its environmental footprint.

Streamlining Production and Not Burdening Subsequent Processes

Foamtec International’s precision in die-cut tooling design minimizes the need for additional processing because parts are produced accurately and consistently. This production efficiency saves resources and reduces time and labor costs for our customers.

Reducing Carbon Emissions Through Efficient Tooling Design

An often overlooked aspect of optimized die-cut tooling design is its potential to reduce carbon emissions. Foamtec International’s advanced tooling solutions contribute to sustainability by:

-

Lowering Energy Consumption: Efficient designs require less machine time and energy per cut, which reduces the carbon footprint associated with manufacturing processes.

-

Minimizing Transportation: Maximizing material utilization and reducing waste also reduces the need to transport raw materials and waste disposal, further lowering carbon emissions.

-

Promoting Sustainable Materials: Foamtec’s R&D is committed to providing recyclable and eco-friendly materials

Foamtec International’s Sustainable Initiatives

Foamtec International is committed to adopting renewable energy sources in its manufacturing facilities. Our facilities are ISO 14001 certified, signifying the implementation and maintenance of an effective Environmental Management System (EMS). The ISO 14001 demonstrates dedication to reducing our carbon footprint in every aspect of manufacturing.

Foamtec International’s efforts highlight the importance of awareness and innovation in environmental responsibility. It’s a future we intend to lead the way in for a healthier planet for future generations.