In the intricate world of electronics and electrical systems, where miniaturization meets power and precision, insulation is not just a protective layer – it’s a critical component for performance, reliability, and safety. While often unseen, a range of high-performance plastic films act as invisible shields, preventing short circuits, managing heat, and ensuring the seamless operation of countless devices. Among the most prominent of these are films made from Polypropylene (PP), Polycarbonate (PC), and Polyethylene Terephthalate (PET), each with unique properties tailored to specific usage scenarios.

The Role of Insulating Films: Beyond Simple Barriers

Electrical insulation films serve multiple vital functions:

- Dielectric Barrier: Their primary role is to prevent the flow of electricity between conductive parts, ensuring that current follows its intended path. This is quantified by their dielectric strength, which measures the maximum electric field they can withstand before breaking down and becoming conductive. A higher dielectric strength indicates superior insulating capability.

- Thermal Management: Electronic components generate heat. Insulating films often need to withstand continuous operating temperatures and dissipate heat effectively to prevent overheating and premature failure.

- Mechanical Protection: Films provide physical separation and protection against abrasion, tearing, and impact, especially in flexible circuits or high-vibration environments.

- Chemical Resistance: They must resist degradation from chemicals, moisture, and environmental factors that could compromise their insulating properties over time.

- Flame Retardancy: In many applications, especially those dealing with power, films must be flame retardant to prevent the spread of fire in case of an electrical fault.

Key Players: PP, PC, PET, and Others

Let’s delve into the characteristics and typical applications of these common insulating films:

1. Polypropylene (PP) Film

- Characteristics: PP films are known for their excellent dielectric properties, low dielectric loss, and good chemical resistance. They have a relatively low dielectric constant, which is beneficial for high-frequency applications where minimizing capacitance is important. PP also exhibits good flexibility. However, its natural flammability requires flame-retardant additives for many electrical applications.

- Usage Scenarios:

- Capacitors: PP film is a widely used dielectric in film capacitors due to its high breakdown strength and low dielectric loss, making it ideal for energy storage in power electronics, audio equipment, and motor run/start circuits.

- Wire and Cable Insulation: Its flexibility and dielectric strength make it suitable for insulation in various wire and cable applications, especially where high frequency signals are involved.

- Battery Separators: In certain battery technologies, PP films can be used as separators due to their chemical stability and insulating properties.

2. Polycarbonate (PC) Film

- Characteristics: PC films offer a unique combination of high impact strength, excellent dimensional stability, good optical clarity (for clear grades), and good electrical insulation properties. They can withstand relatively high temperatures and are often available in flame-retardant (FR) grades that meet UL 94 V-0 standards.

- Usage Scenarios:

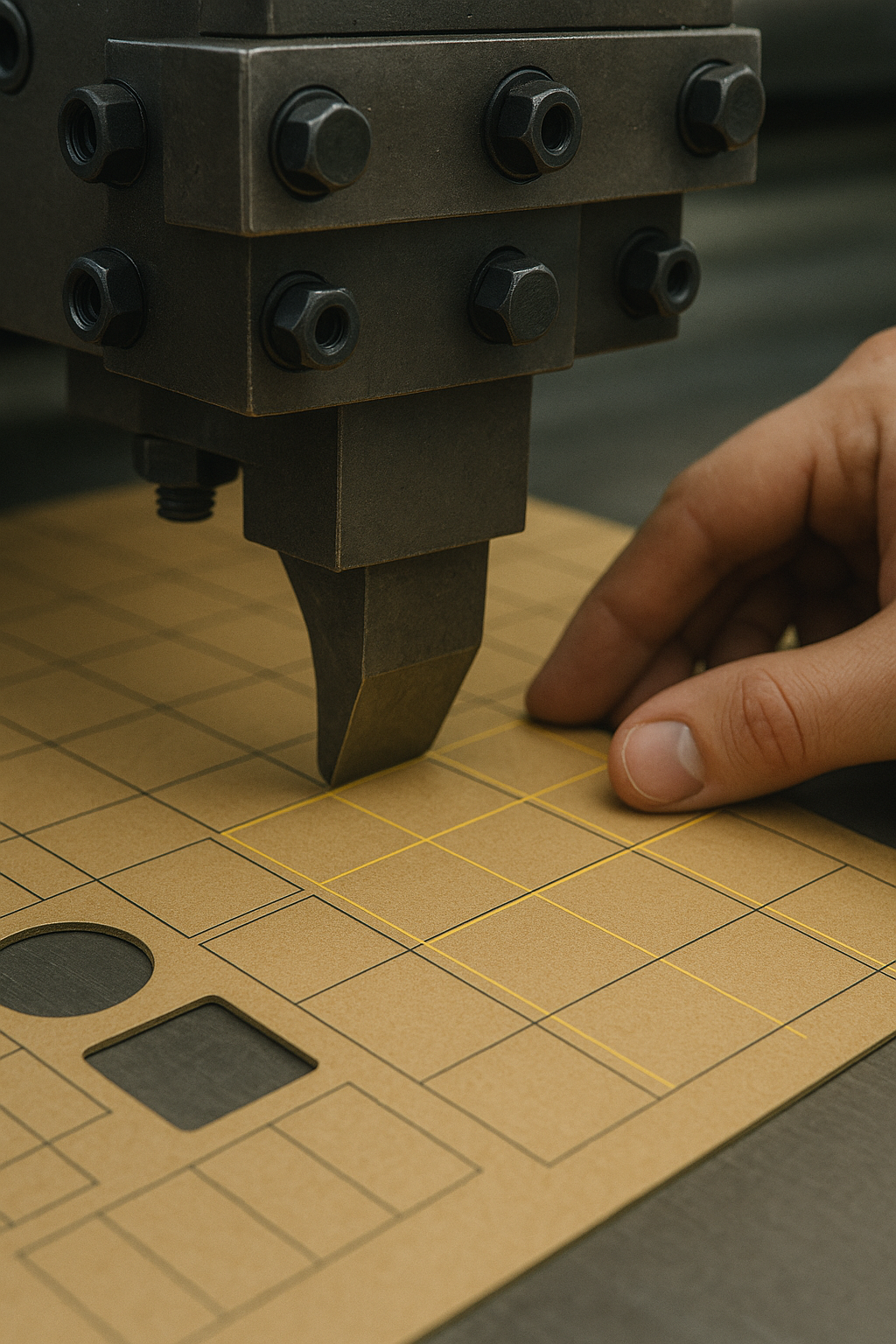

- Die-cut Insulators and Spacers: Due to their toughness and dimensional stability, PC films are frequently die-cut into insulators, barriers, and spacers within electronic devices, circuit boards (PCBs), and control panels.

- Overlays and Panels: Their clarity and printability make them suitable for transparent protective layers over displays, touch interfaces, and control panel overlays.

- Battery Housings and Covers: In electric vehicles and portable devices, flame-retardant PC films are used for battery component insulation and covers due to their impact resistance and safety ratings.

- Lighting Fixtures: Used in LED enclosures, lenses, and diffusers, where a combination of electrical insulation, clarity, and heat resistance is required.

3. Polyethylene Terephthalate (PET) Film

- Characteristics: Often known by brand names like Mylar® or Melinex®, PET films are renowned for their excellent balance of mechanical strength (high tensile strength), good dielectric properties, thermal stability, and chemical resistance. They offer a good cost-to-performance ratio. While PET has good thermal endurance, its corona resistance can be poor at high voltages, making it generally unsuitable for very high-voltage applications without additional treatments.

- Usage Scenarios:

- Motor and Transformer Insulation: PET films are extensively used as slot liners, phase insulation, and coil wraps in motors, transformers, and generators due to their thermal and dielectric properties.

- Flexible Printed Circuits (FPCs): As a substrate or insulating layer in flexible circuits due to its dimensional stability and good electrical properties.

- Wire and Cable Wrap: Providing insulation and mechanical protection for conductors in various cable constructions.

- Membrane Touch Switches: As a durable and dimensionally stable base film for membrane switch circuits.

Other Notable Films

Beyond PP, PC, and PET, other specialized films play crucial roles:

- Polyimide (PI) Film (e.g., Kapton®): Offers exceptional thermal stability (very high Relative Thermal Index – RTI), excellent dielectric strength, and chemical resistance. Ideal for extreme temperature applications, flexible PCBs, and high-performance wire insulation.

- PEN (Polyethylene Naphthalate) Film (e.g., Teonex®): Provides improved thermal stability and mechanical properties compared to PET, making it suitable for more demanding applications.

- PTFE (Polytetrafluoroethylene) Film (e.g., Teflon™): Known for its extremely low dielectric constant and dissipation factor, excellent high-frequency performance, and superior chemical and temperature resistance. Used in high-frequency cables, specialized electronics, and harsh environments.

The Critical Characteristics: Durability and Safety

The selection of an insulating film is a meticulous process, weighing various characteristics to ensure both durability and safety:

- Thickness: Directly impacts dielectric strength. Generally, a thicker film provides higher dielectric strength, but also increases material usage and can affect form factor. Engineers optimize thickness to meet voltage requirements while minimizing space and cost.

- Dielectric Strength (V/mil or kV/mm): This is perhaps the most critical electrical property. It indicates how much voltage a film can withstand per unit of thickness before electrical breakdown. A higher value means better insulation.

- Relative Thermal Index (RTI): This crucial UL rating (Underwriters Laboratories) defines the long-term thermal endurance of a plastic material. It represents the maximum temperature at which a material can be exposed continuously for 60,000 hours without its critical properties (electrical, mechanical with and without impact) degrading below 50% of their initial value. A higher RTI signifies greater thermal stability and a longer service life in high-temperature environments.

- UL/FR (Flammability Rating): UL 94 is a plastics flammability standard. Films are rated based on their ability to self-extinguish or resist flame propagation. Common ratings like UL 94 V-0 (vertical burning, extinguishes quickly, no flaming drips) are essential for safety-critical electronic applications, ensuring that in case of a fault, the insulation does not contribute to fire spread.

- Tensile Strength and Elongation: Indicate the film’s ability to withstand pulling forces and its flexibility before breaking. Important for handling during manufacturing, and for applications where the film might be bent or stretched.

- Dielectric Constant (Permittivity): Measures a material’s ability to store electrical energy in an electric field. Lower dielectric constants are generally preferred for high-frequency applications to minimize signal loss.

- Dissipation Factor (Loss Tangent): Indicates the amount of energy lost as heat within the insulation when subjected to an alternating electric field. Low dissipation factors are critical for efficiency, especially in high-frequency circuits.

- Moisture Absorption: High moisture absorption can degrade electrical properties over time, leading to insulation breakdown. Films with low moisture absorption are preferred for humid environments.

- Chemical Resistance: Resistance to solvents, oils, and other chemicals encountered during manufacturing or operation is vital for long-term reliability.

Foamtec International: Pioneering Solutions in Electrical Insulation

For 28 years, Foamtec International has been a trusted name in advanced material conversion, with deep expertise in providing critical components for the electronics and electrical industries. Their long-standing experience and professional know-how in die cutting and converting a wide array of high-performance films mean they possess an unparalleled understanding of how PP, PC, PET, and other specialized insulating films behave under various conditions.

Foamtec International’s extensive experience allows them to precisely select and process the ideal film based on:

- Specific application requirements: Matching the film’s thermal, electrical, and mechanical properties to the demands of the end product.

- Regulatory compliance: Ensuring films meet stringent industry standards such as UL ratings for flammability and thermal endurance.

- Optimized thickness and form factor: Delivering die-cut parts with the exact dimensions and tolerances required for efficient assembly and optimal performance.

- Cost-effectiveness: Balancing performance requirements with material and processing costs to provide efficient solutions.

Their capabilities extend across the entire spectrum of high-tech industries, including advanced electronics, demanding automotive systems, precision medical devices, and robust consumer electronics. Foamtec International’s commitment to quality and innovation ensures that the unseen shield of insulation within your devices is always engineered for maximum durability and uncompromising safety.