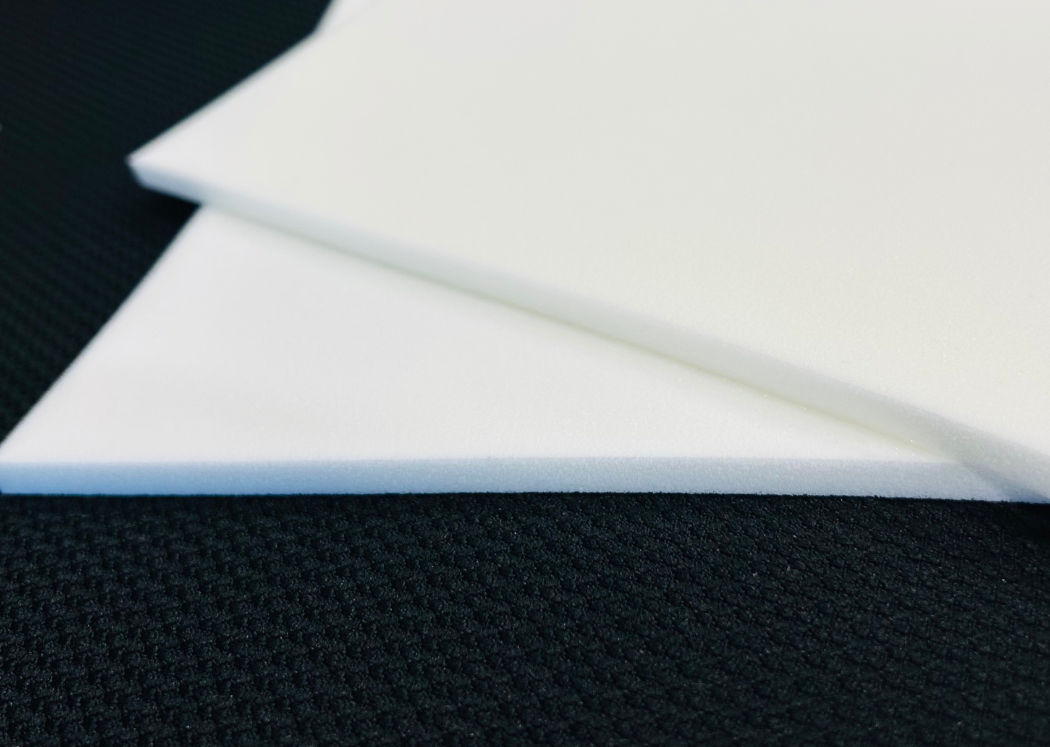

Vertical cutting involves slicing blocks of material mounted on a vertical surface using specialized cutting tools and machines. This orientation enables clean, accurate cuts with reduced waste and allows for the production of custom shapes and sizes that meet the specific requirements of each industry.

Vertical Cutting

Experience The Foamtec Way

Vertical Cutting: The Process

Benefits of Vertical Cutting

Applications

Vertical cutting is widely used across several industries due to its versatility and accuracy:

Furniture & Upholstery

Materials are cut to specific shapes and sizes for use in sofas, mattresses, and other seating solutions.

Packaging

Custom-cut protective inserts ensure products are safely transported and delivered.

Automotive & Aerospace

Precise cuts provide components for seating, insulation, and shock absorption, ensuring a perfect fit.

Medical

Materials are tailored for use in medical beds, wheelchairs, and other supportive devices, enhancing both comfort and functionality.

Let's Innovate Together.

Interested in working together? Contact our team today.

High-Quality Products

At Foamtec Specialty Converting, our vertical cutting capabilities deliver high-quality, efficient, and customized solutions that meet the diverse needs of our clients across various industries.

Learn More