Die-cut tapes play a crucial role in the electronics industry, particularly in the assembly, packaging, and insulation of electronic components and devices. Die-cutting is a manufacturing process that involves cutting materials, such as adhesive tapes, into specific shapes and sizes using a specialized cutting tool called a die. Die-cut tapes are used for various purposes in the electronics industry, including:

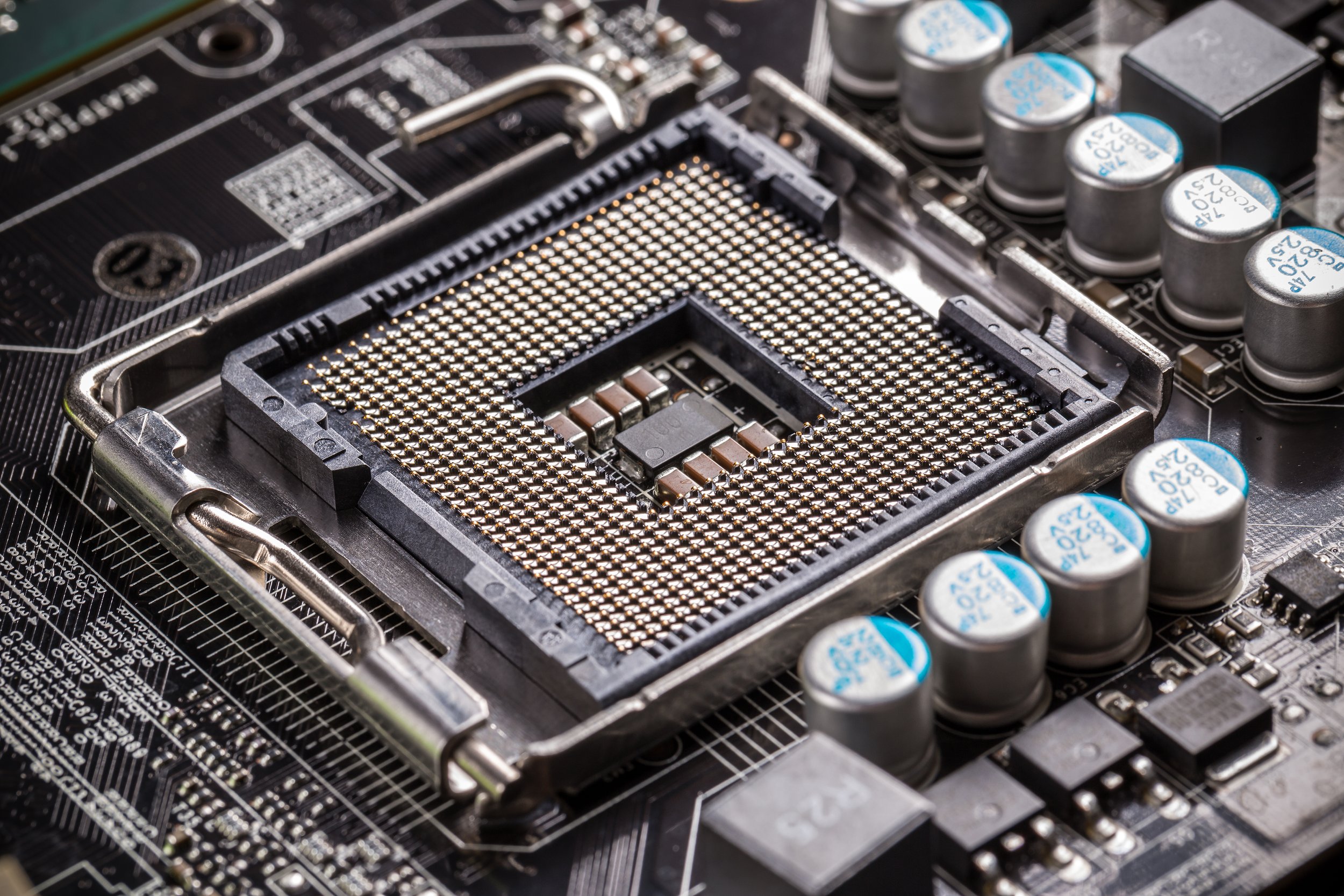

Component Mounting and Bonding: Die-cut tapes are used to mount and bond electronic components to circuit boards and other surfaces. These tapes often have strong adhesive properties to ensure a secure and reliable bond.

Insulation: Die-cut tapes provide electrical insulation for electronic components and circuits. They help prevent short circuits and ensure the safety and functionality of the electronics.

EMI/RFI Shielding: Die-cut tapes can create shields that protect electronic devices from electromagnetic interference (EMI) and radio frequency interference (RFI), which are essential for maintaining proper functionality and preventing data corruption.

Gasketing: Die-cut gaskets made from tape seal electronic enclosures protect the internal components from moisture, dust, and other environmental factors.

Masking: Die-cut tapes are used for masking specific areas during processes like painting or coating, ensuring that only designated areas are affected.

Heat Dissipation: Die-cut tapes with thermal conductivity properties are used to aid in efficiently dissipating heat from electronic components. This is crucial for preventing overheating and maintaining optimal performance.

Flex Circuit Bonding: Die-cut tapes bond flexible circuits to other components or surfaces in electronic devices.

Cable Management: Die-cut tapes are utilized for cable bundling, organization, and management, ensuring neat and secure wiring in electronic devices.

The die-cutting process allows for precision and consistency in producing tapes with specific dimensions and shapes tailored to the unique requirements of electronic applications. It enables manufacturers to optimize the use of materials, improve efficiency, and enhance the performance and reliability of electronic products.

At Foamtec International Specialty Converting, we take pride in our ability to collaborate closely with our partners, understanding their unique product requirements and delivering custom die-cut solutions that enhance product performance, reduce waste, and streamline production processes.

Our state-of-the-art die-cutting technology and our expertise in materials selection allow us to provide precision-cut components that meet the highest industry standards.

Partner with Foamtec International Specialty Converting for all your custom die-cutting needs in the electronics industry. Contact us today to discuss your specific requirements and discover how our expertise and cutting-edge technology can elevate your electronic products to new levels of excellence.