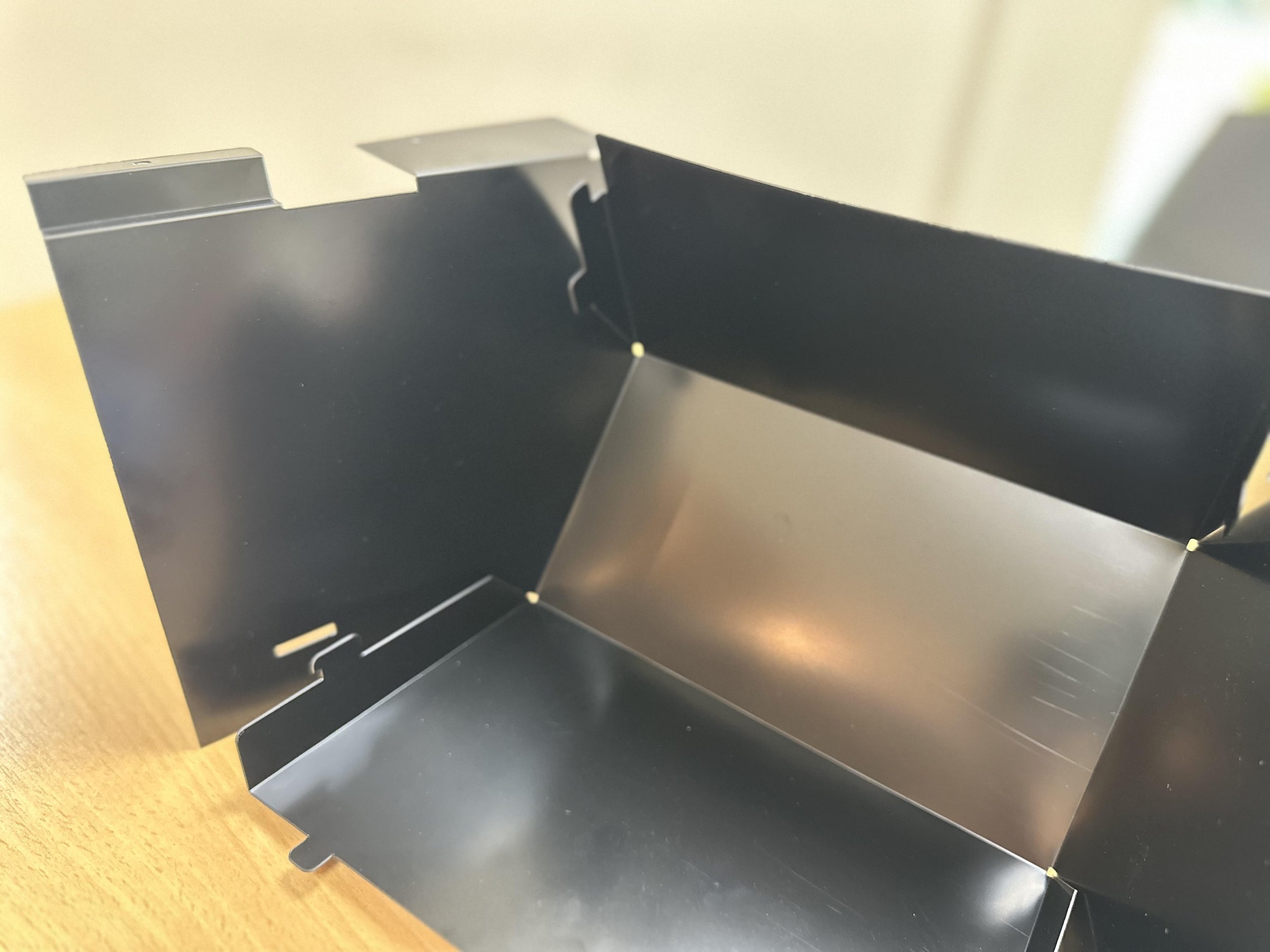

In the vast and intricate world of electronics, every component plays a pivotal role in ensuring the final product’s efficiency, reliability, and safety. Folded insulation parts hold a special place among these components due to their unique functionality and the precise engineering required in their fabrication. These components are essential in managing heat dissipation, electrical insulation, and physical protection within electronic devices.

Why Folded Parts?

Folded insulation parts are integral to electronic and electrical devices for several reasons:

-

Enhanced Insulation: These components’ primary function is to insulate electrical parts from each other, preventing short circuits and protecting the user from electric shocks. The folding increases the surface area without compromising compactness, enhancing the insulation properties.

-

Improved Heat Management: Electronics generate heat, and managing this heat is crucial to maintain the integrity and longevity of the device. Folded parts can be designed to aid in heat dissipation, acting as barriers or channels that guide heat away from sensitive components.

-

Space Optimization: Folded insulation parts can conform to complex shapes and fit into tight spaces, providing insulation and protection without wasting precious real estate within the device.

Safety Features in Folded Insulation Parts

Safety is paramount in the design and manufacturing of electronic devices. Folded insulation parts not only contribute to the functional and structural integrity of these devices but also incorporate crucial safety features that protect both the device and its users. The design of these parts is informed by a thorough understanding of the risks involved in electronic circuits, including electrical overheating, short circuits, and user exposure to electrical components.

Preventing Electrical Overheating

One of the key safety features of folded insulation parts is their role in preventing electrical overheating. By effectively managing and dissipating heat, these components reduce the risk of overheating in electronic devices, which can cause fires or damage sensitive components. Materials selected for folded parts, such as high-thermal-resistance foams and films, are chosen for their ability to withstand high temperatures while maintaining their insulating properties.

Protection Against Electrical Shocks

Folded insulation parts also provide a critical barrier between the user and the electrical components inside a device. This barrier is essential for preventing accidental electrical shocks, which can occur if a user comes into contact with live electrical parts. The folding of these insulation materials increases their effectiveness by enhancing the physical separation between the user and the components while also fitting into the compact designs of modern electronics.

Enhancing Durability and Reliability

Safety in electronics also pertains to the durability and reliability of the device. Folded insulation parts contribute to this aspect by protecting sensitive components from physical shocks and environmental factors, such as moisture or dust, which could compromise the device’s functionality over time. This protection ensures that the device operates safely during its initial use and continues to provide safe and reliable performance throughout its lifespan.

Materials for Folded Insulation Parts

The choice of material for folded insulation parts is guided by the specific requirements of the application, including thermal conductivity, electrical resistance, mechanical strength, and flexibility. Common materials include:

-

Polyimide Films: Known for their excellent thermal stability and electrical insulation properties, polyimide films are widely used in high-performance applications.

-

Foam Materials: Various foam materials, such as polyethylene or polyurethane foams, offer good insulation, shock absorption, and can be easily compressed and folded.

-

Non-Woven Fabrics: These materials are used for their breathability, flexibility, and good insulation properties, making them suitable for applications requiring airflow and insulation.

Foamtec International’s Expertise

Foamtec International stands out as a leader in fabricating folded insulation parts for electronics. With years of experience and a commitment to innovation, Foamtec has developed specialized techniques and materials that cater to the demanding needs of the electronics industry. Their expertise encompasses:

-

Custom Engineering Solutions: Foamtec excels at creating tailored solutions that meet each client’s precise requirements from the initial design phase to the final product.

-

Advanced Material Science: Leveraging advanced materials, Foamtec offers products that provide superior insulation, thermal management, and durability.

-

Quality and Precision: Foamtec’s manufacturing processes ensure high-quality components with precise folding and cutting, which is crucial for the performance and reliability of the insulation parts.

Folded insulation parts are crucial for electronic device performance, safety, and efficiency. Carefully selected materials and specialized fabrication techniques are key to their functionality. Companies like Foamtec International play an essential role in advancing the field, bringing expertise and innovation to the development of these vital components. They ensure that electronics continue to evolve in their capabilities while maintaining the highest standards of safety and performance.